Metal crusher

- 【Feeding Size】:≤1000mm

- 【Processing capacity】:≤5.5t/h

- 【Motor power】:30kw-200kw

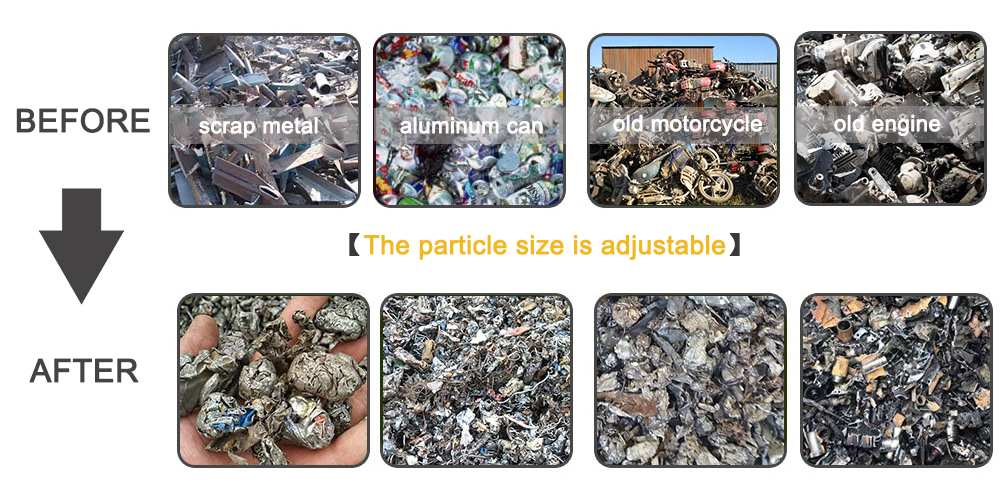

- 【Handling materials】:Crushing and recycling various raw aluminum, aluminum alloys, aluminum profiles, bridge-cut aluminum, and discarded aluminum cans...

【Keyword】:

- Scrap Iron Crusher

- Waste car shell crusher

- Waste metal recycling and processing equipment

Product Introduction

Wide range of applicationsIt is capable of shredding various metals such as iron, steel, and aluminum, and can also handle waste cables, scrap steel bars, etc., making it suitable for a wide range of application scenarios.High durability: The equipment is made of high-strength wear-resistant materials, extending its service life and reducing maintenance costs.

A metal crusher is a specialized mechanical device designed for crushing metal materials. It can efficiently crush various forms of metal scraps, such as scrap steel, aluminum alloy, copper, etc., into particles or blocks that meet the requirements for subsequent processing or recycling. This reduces the transportation costs of scrap metal and achieves better profit prospects in terms of recycling prices. The main body of the equipment is constructed using thickened steel plates, with an inner lining of high-manganese cast steel to protect the outer body. At the rotor part of the main machine, a disc-type fastening rotating mechanism is adopted.

When purchasing a metal crusher, users also need to consider factors such as equipment durability, maintenance costs, and after-sales service. A high-quality metal crusher should feature a reasonable structure, excellent materials, and superb craftsmanship, capable of stable operation for a long time without frequent maintenance. At the same time, the after-sales service provided by the manufacturer is also one of the important factors for users to consider. Good after-sales service can ensure that users receive timely technical support and maintenance services during use.

Product advantages

Equipped with high-performance alloy blades, it can quickly process a large quantity of scrap metal with uniform crushing results.

It supports an automatic control system, enabling one-click start, intelligent monitoring, and fault alarms, making it convenient for use and maintenance.

It is capable of shredding various metals such as iron, steel, and aluminum, and can also handle waste cables, scrap steel bars, etc., making it suitable for a wide range of application scenarios.

The equipment is made of high-strength wear-resistant materials, extending its service life and reducing maintenance costs.

working principle

The working principle of a metal crusher revolves around four core stages: "feeding, crushing, screening, and discharging". It utilizes mechanical impacts, extrusions, shearing, and other mechanisms to achieve the crushing and processing of metal materials. In the feeding stage, the metal materials to be crushed enter the equipment through a feeding hopper. Some equipment is equipped with vibrating feeding devices or conveyor belts, which can evenly and continuously transport the materials to the crushing chamber, preventing material accumulation at the feeding inlet and resulting in blockages. Additionally, the feeding speed can be controlled through a feeding adjustment device to accommodate metal materials of different sizes and hardnesses. Upon entering the crushing stage, the rotor inside the crushing chamber serves as the core working component. The rotor is driven by a motor through a belt drive or a coupling, rotating at high speed (typically at 500-1500r/min). Multiple hammerheads (such as high-manganese steel hammerheads and alloy hammerheads) are mounted on the rotor. When metallic materials enter the crushing chamber, the high-speed rotating hammerheads exert a strong impact force on the materials, breaking down large pieces. Simultaneously, the materials undergo mutual squeezing, friction, and shearing within the crushing chamber with the lining plate and other materials, further refining the particle size of the materials. For metallic materials with higher hardness (such as scrap steel), the synergistic action of the hammerheads and the lining plate effectively overcomes the strength of the materials, achieving crushing. For softer metallic materials (such as aluminum products), crushing is primarily achieved through impact and shearing.

Surgical parameters

| Model | Power(kw) | Output(kg/h) | Host Size(m) |

| 600 | 18.5-22 | 200-400 | 2.6×1.5×1.85 |

| 700 | 20-30 | 400-800 | 2.8×1.8×1.95 |

| 800 | 30-37 | 500-1000 | 2.9×2.3×2.0 |

| 900 | 37-45 | 600-1200 | 2.9×2.5×2.13 |

| 1000 | 75-110 | 1000-2000 | 3.2×2.6×2.3 |

| 1300 | 90-110 | 3000-5500 | 3.8×3.0×2.8 |

Hot Line:008613044703777

Time:9:00 - 18:00