Scrap steel crusher

- 【Feeding Size】:≤1000mm

- 【Processing capacity】:0.8-15t/h

- 【Motor power】:30kw-450kw

- 【Handling materials】:Scrap steel, aluminum alloy, scrapped household appliances/cars...

- 【】:

【Keyword】:

- Scrap steel crusher

- aluminum alloy crusher

- scrap household appliances/car crusher

Product Introduction

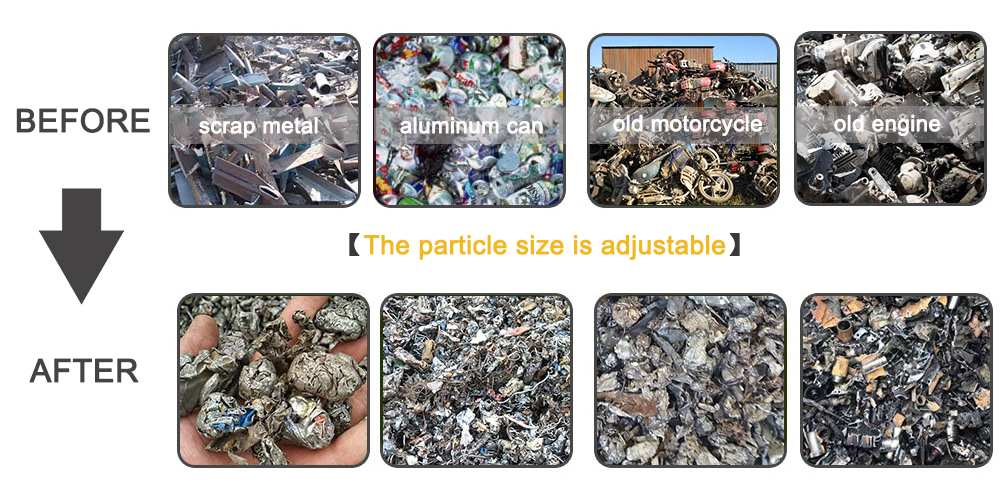

Scrap steel crusher is widely recognized as an ideal crushing equipment for processing various large steel scrap. It is generally used for batch crushing of scrapped cars, household appliances, bicycles, motorcycles, and car shells. The scrap steel material processed by the scrap steel crusher has a high volume density, high purity, few impurities, and high economic value. The crushed material can be directly remelted by the steel plant, with low energy consumption, high output, and very high comprehensive economic benefits.

The scrap steel crusher can separate surface contaminants such as rust and paint from the scrap steel during crushing, and then, under the action of a magnetic sorting device, separate non-metallic waste such as non-ferrous metals, plastics, and rubber mixed in the scrap steel into separate piles. Not only can pure crushed steel be obtained, but also non-ferrous metals can be manually selected and recycled. The bulk density of pure crushed steel ingots, billets, and similar materials can reach 1.3t/m ³, making it an ideal material for electric furnace steelmaking.

The scrap steel crusher is a core crushing equipment dedicated to the recycling and reuse of scrap metal resources. It is also one of the main equipment in the scrap steel crushing and recycling production line. Its function is to crush lightweight metal sheets into small pieces for easy sorting, and obtain relatively pure black metal raw materials. The crusher can crush various metal cans, beverage cans, paint cans, machine oil tanks and other metals. And this crushed metal material is easy to transport, convenient for feeding into steelmaking, and the number of feeding times is also greatly reduced. Its crusher has high efficiency, stable performance, and good applicability.

Product advantages

Equipped with high-performance alloy blades, it can quickly process a large quantity of scrap metal with uniform crushing results.

It supports an automatic control system, enabling one-click start, intelligent monitoring, and fault alarms, making it convenient for use and maintenance.

It is capable of shredding various metals such as iron, steel, and aluminum, and can also handle waste cables, scrap steel bars, etc., making it suitable for a wide range of application scenarios.

The equipment is made of high-strength wear-resistant materials, extending its service life and reducing maintenance costs.

working principle

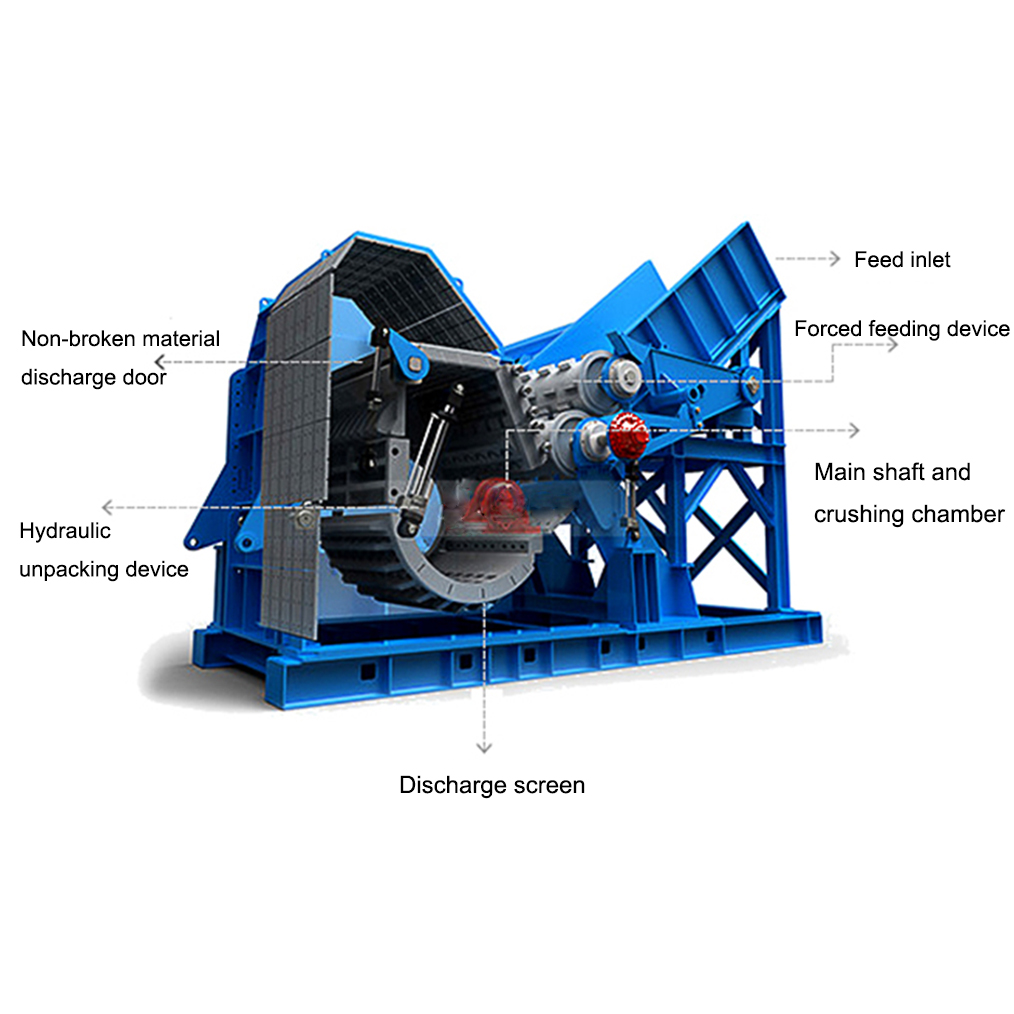

The motor of the scrap steel crusher drives the rotor to rotate rapidly, and the hammer head on the rotor comes into fierce contact with the scrap steel, producing strong impact, friction, and cutting effects, thus being able to crush the scrap steel. This powerful crushing effect allows scrap steel of various shapes and sizes to be quickly decomposed. In practical use, it can easily crush large waste steel plates, steel bars, etc. into small particles, preparing for subsequent processing and recycling. When it is running, the raw materials enter the crushing chamber through the inlet, and after repeated hitting and friction inside, the standard sized fragments fall out from the outlet end. The construction and layout of the machine can ensure smooth and reliable crushing operations, significantly improving the processing capacity of scrap iron.

Surgical parameters

| Model | Power(kw) | Output(kg/h) | Host Size(m) |

| 600 | 18.5-22 | 200-400 | 2.6×1.5×1.85 |

| 700 | 20-30 | 400-800 | 2.8×1.8×1.95 |

| 800 | 30-37 | 500-1000 | 2.9×2.3×2.0 |

| 900 | 37-45 | 600-1200 | 2.9×2.5×2.13 |

| 1000 | 75-110 | 1000-2000 | 3.2×2.6×2.3 |

| 1300 | 90-110 | 3000-5500 | 3.8×3.0×2.8 |

Hot Line:008613044703777

Time:9:00 - 18:00