Cans crusher

- 【Feeding Size】:≤1000mm

- 【Processing capacity】:0.8-15t/h

- 【Motor power】:30kw-450kw

- 【Handling materials】:Waste paint buckets, cans and pots, pastry boxes, various aluminum cans, scrap iron sheets, scrap iron slag, aluminum profiles, copper bars, tubes, and old motor casings

【Keyword】:

- Scrap iron sheet crusher

- aluminum profile crusher

- scrap motor shell crusher

Product Introduction

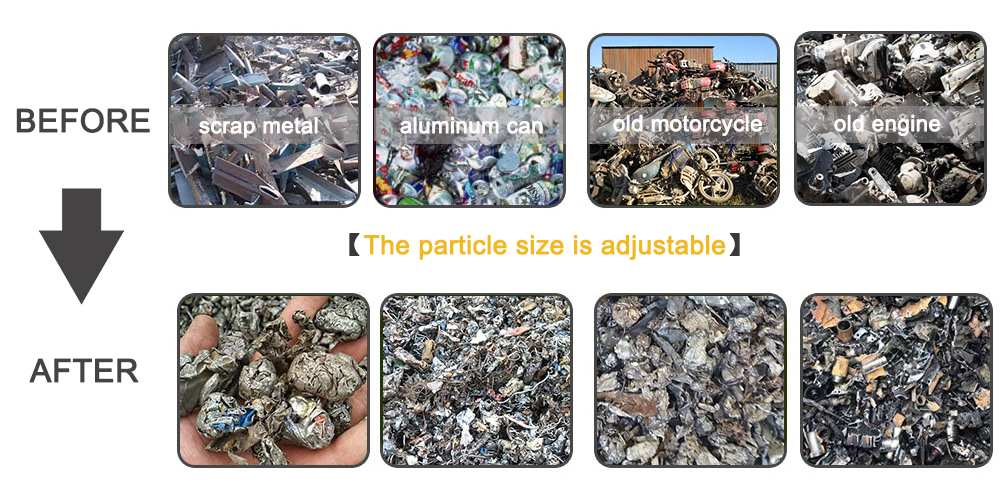

An aluminum can crusher is a specialized mechanical device designed to crush metal scraps such as aluminum cans. It utilizes high-speed rotating blades to cut and crush metal scraps into small pieces, facilitating subsequent recycling and processing. This equipment is widely used in waste recycling stations, metal processing plants, environmental protection treatment centers, and other similar locations. The working principle of an aluminum can crusher involves a motor-driven blade that rotates at high speed, cutting the input metal scraps such as aluminum cans into small fragments. These fragments are then filtered through a screen to obtain the desired fragment size.

The core components of a can crusher include blades, a motor, a screen mesh, and a frame. The blades are typically made of high-speed steel, which boasts high hardness and wear resistance, ensuring they remain sharp for an extended period. The motor provides the power, typically operating on 380V voltage, with power varying depending on the processing capacity. The screen mesh controls the size of the crushed fragments and can be replaced with screens of different pore sizes according to requirements. The frame serves to support and secure all components, ensuring stable operation of the equipment.

The processing capacity of a can crusher typically ranges from 100 to 3000KG/H, depending on the model and configuration of the equipment. The equipment is primarily suitable for natural fibers, but it is also applicable to other types of metal scraps. The equipment is often colored orange for easy identification and maintenance. Its application areas mainly include waste recycling, metal processing, and environmental protection treatment. Its primary purpose is to crush metal scraps, facilitating subsequent recycling and reuse.

When using a can crusher, the following points should be noted: Firstly, ensure that the equipment is installed on a stable ground to avoid vibration during operation. Secondly, regularly check the wear of the blades and replace severely worn blades in a timely manner to ensure the crushing effect. Thirdly, avoid feeding excessive metal scraps to prevent damage to the equipment. Finally, wear protective gear during operation to ensure safety.

The maintenance of the aluminum can crusher is also crucial. Regularly clean the residual debris inside the equipment to prevent blockages. Check the operating status of the motor to ensure there are no abnormal noises or overheating. Lubricate the moving parts of the equipment to reduce wear. Through proper use and maintenance, the service life of the equipment can be extended and work efficiency can be improved.

Product advantages

Equipped with high-performance alloy blades, it can quickly process a large quantity of scrap metal with uniform crushing results.

It supports an automatic control system, enabling one-click start, intelligent monitoring, and fault alarms, making it convenient for use and maintenance.

It is capable of shredding various metals such as iron, steel, and aluminum, and can also handle waste cables, scrap steel bars, etc., making it suitable for a wide range of application scenarios.

The equipment is made of high-strength wear-resistant materials, extending its service life and reducing maintenance costs.

working principle

The working mode of the can crusher is to use a motor to drive the fan wheel for extrusion. The high-speed high torque motor provides powerful power, allowing the items sent into the crushing chamber to be fully crushed. The motor continues to exert stable force, and the wind turbine rotates at high speed, exerting strong pressure on the object to be crushed, gradually tearing it into fragments that meet the standards. In the material decomposition process, the filtering device plays an important role as it can accurately adjust the size of the finished product to meet the requirements of material particle size in various situations. For example, in some recycling sites, this technology can quickly process many aluminum cans. These recycling stations collect a large number of aluminum cans every day. With the help of metal can crushing equipment, they can be quickly crushed for future reuse and significantly improve the efficiency of recycling work The discharge distribution of the can crusher is uniform, and the particle size can be adjusted. And the worn parts of the equipment are made of special materials, which are durable and help reduce operating expenses. Its construction is scientific, compact in size, and does not take up much space. For example, it can be easily placed in recycling facilities with limited space. In addition, the running sound is gentle, reducing interference with the surrounding environment and improving the comfort of the job.

Surgical parameters

| Model | Power(kw) | Output(kg/h) | Host Size(m) |

| 600 | 18.5-22 | 200-400 | 2.6×1.5×1.85 |

| 700 | 20-30 | 400-800 | 2.8×1.8×1.95 |

| 800 | 30-37 | 500-1000 | 2.9×2.3×2.0 |

| 900 | 37-45 | 600-1200 | 2.9×2.5×2.13 |

| 1000 | 75-110 | 1000-2000 | 3.2×2.6×2.3 |

| 1300 | 90-110 | 3000-5500 | 3.8×3.0×2.8 |

Hot Line:008613044703777

Time:9:00 - 18:00