Color steel tile crusher

- 【Feeding Size】:≤1000mm

- 【Processing capacity】:≤5.5t/h

- 【Motor power】:30kw-200kw

- 【Handling materials】:Thin metal sheets, discarded car shells/motorcycles/bicycles/paint buckets/gasoline barrels

【Keyword】:

- Thin metal sheet crusher

- Scrapped car shell crusher

- Waste bicycle crusher

- Waste motorcycle crusher

Product Introduction

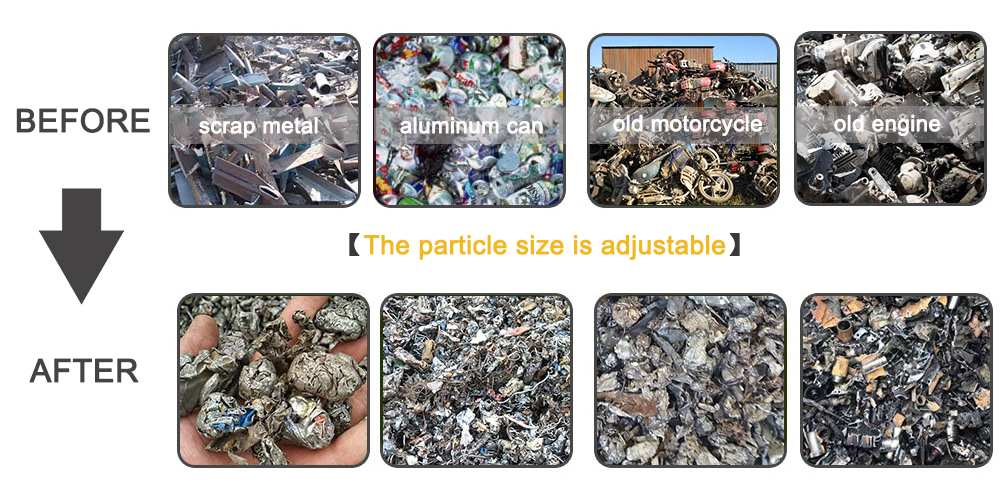

During the operation of the color steel tile crusher, the high-speed rotation of the main shaft drives the hammer head to strike the metal material at high speed, which, together with the impact lining plate, completes the crushing process of waste color steel tiles. The large pieces of waste metal are crushed into granular metal, facilitating long-distance transportation and subsequent metallurgical recycling treatment.

Color steel tile crushers are widely used in waste material recycling applications nowadays. These devices can crush and process various types of waste metal materials into metal raw materials required for smelting. Color steel tile crushers not only generate profits for material recycling enterprises but also facilitate the secondary utilization of metal materials, conserve resources, protect the environment, and make significant contributions to environmental protection.

The color steel tile crusher is primarily a device used for crushing waste color steel tiles, iron sheet car radiators, paint buckets, gasoline barrels, aluminum cans, thin iron sheets, iron scraps, and other thin metal materials into spherical particles. It features a stable and compact structure, and is easy to maintain.

Product advantages

Equipped with high-performance alloy blades, it can quickly process a large quantity of scrap metal with uniform crushing results.

It supports an automatic control system, enabling one-click start, intelligent monitoring, and fault alarms, making it convenient for use and maintenance.

It is capable of shredding various metals such as iron, steel, and aluminum, and can also handle waste cables, scrap steel bars, etc., making it suitable for a wide range of application scenarios.

The equipment is made of high-strength wear-resistant materials, extending its service life and reducing maintenance costs.

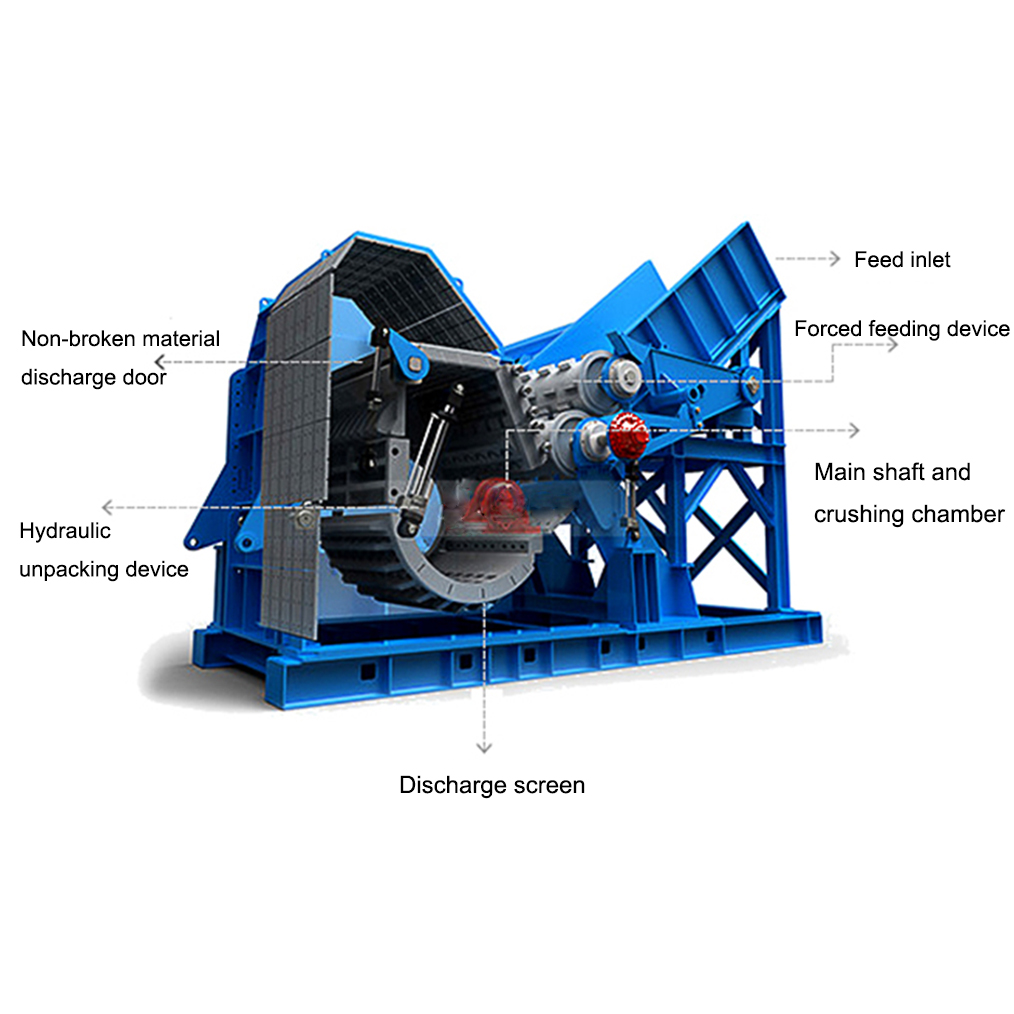

working principle

The color steel tile crusher is primarily driven by a motor, which causes the cutters inside the crusher to rotate at high speed, thereby performing cutting, tearing, and squeezing processes on the color steel tiles entering the crushing chamber. During this process, the color steel tiles are gradually decomposed into smaller fragments. The design of the crushing chamber ensures that the material can fully contact the cutters, thus enhancing the crushing efficiency. Despite its relatively simple working principle, it is highly efficient and can quickly convert large pieces of color steel tiles into small pieces that are easy to handle. Mechanical force is applied to the material for crushing in this way. During the rapid rotation of the cutting tool, the structure of the color steel tile is destroyed. In addition, by properly adjusting the layout and rotational speed of the cutting tool, the crushing requirements of color steel tiles with different thicknesses and materials can be met.

Surgical parameters

| Model | Power(kw) | Output(kg/h) | Host Size(m) |

| 600 | 18.5-22 | 200-400 | 2.6×1.5×1.85 |

| 700 | 20-30 | 400-800 | 2.8×1.8×1.95 |

| 800 | 30-37 | 500-1000 | 2.9×2.3×2.0 |

| 900 | 37-45 | 600-1200 | 2.9×2.5×2.13 |

| 1000 | 75-110 | 1000-2000 | 3.2×2.6×2.3 |

| 1300 | 90-110 | 3000-5500 | 3.8×3.0×2.8 |

Hot Line:008613044703777

Time:9:00 - 18:00