Oil filter crusher

- 【Feeding Size】:≤1000mm

- 【Processing capacity】:0.8-15t/h

- 【Motor power】:30kw-450kw

- 【Handling materials】:Abandoned oil filter, air filter, and air conditioning filter from cars...

【Keyword】:

- Oil filter crusher

- motor rotor crusher

Product Introduction

The oil filter crusher is a mechanical equipment specially designed and manufactured by our technical team for crushing oil filters. After the customer's trial run, it was confirmed to fully meet the requirements. The material processed by the oil filter crusher can easily achieve the crushing of waste oil filters, waste diesel filters, and automotive oil filters. The scrap iron material can be sold as iron, the rubber rings can be crushed into rubber powder and granules for sale, and the remaining filter paper can be used to press out the oil with a press machine. The overall profit is quite considerable.

Due to being covered with various types of engine oil and dust, no one is willing to recycle the material of oil filter cartridges. Some customers have contacted us to design and manufacture oil filter crusher machines tailored to their needs. These machines are specialized in crushing various types of oil filter cartridges. After crushing and magnetic separation, the rubber and scrap metal obtained have a very high economic value.

The oil filter crusher is a specially designed mechanical equipment for crushing oil filters. It completes the processing and separation of oil filters through a complete oil filter crushing production line:

1. The oil filter crusher separates the outer shell and core paper of the oil filter during the crushing process;

2. Separate the iron, rubber rings, springs, and filter paper after separation through a magnetic separator;

After the filter paper is separated, it enters the oil press to press out the oil from the oil filter paper and collect it;

4. In the end, we obtain various useful materials such as waste engine oil, rubber, iron, and springs.

Product advantages

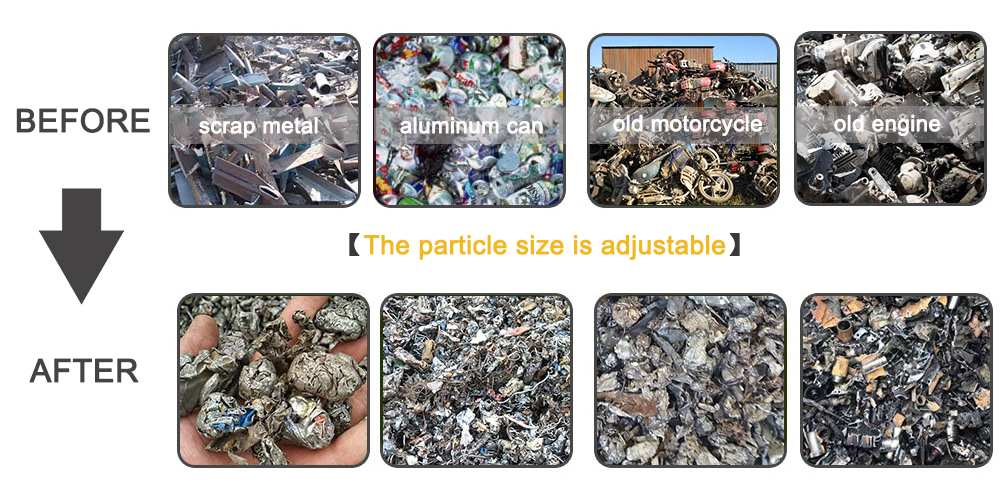

Equipped with high-performance alloy blades, it can quickly process a large quantity of scrap metal with uniform crushing results.

It supports an automatic control system, enabling one-click start, intelligent monitoring, and fault alarms, making it convenient for use and maintenance.

It is capable of shredding various metals such as iron, steel, and aluminum, and can also handle waste cables, scrap steel bars, etc., making it suitable for a wide range of application scenarios.

The equipment is made of high-strength wear-resistant materials, extending its service life and reducing maintenance costs.

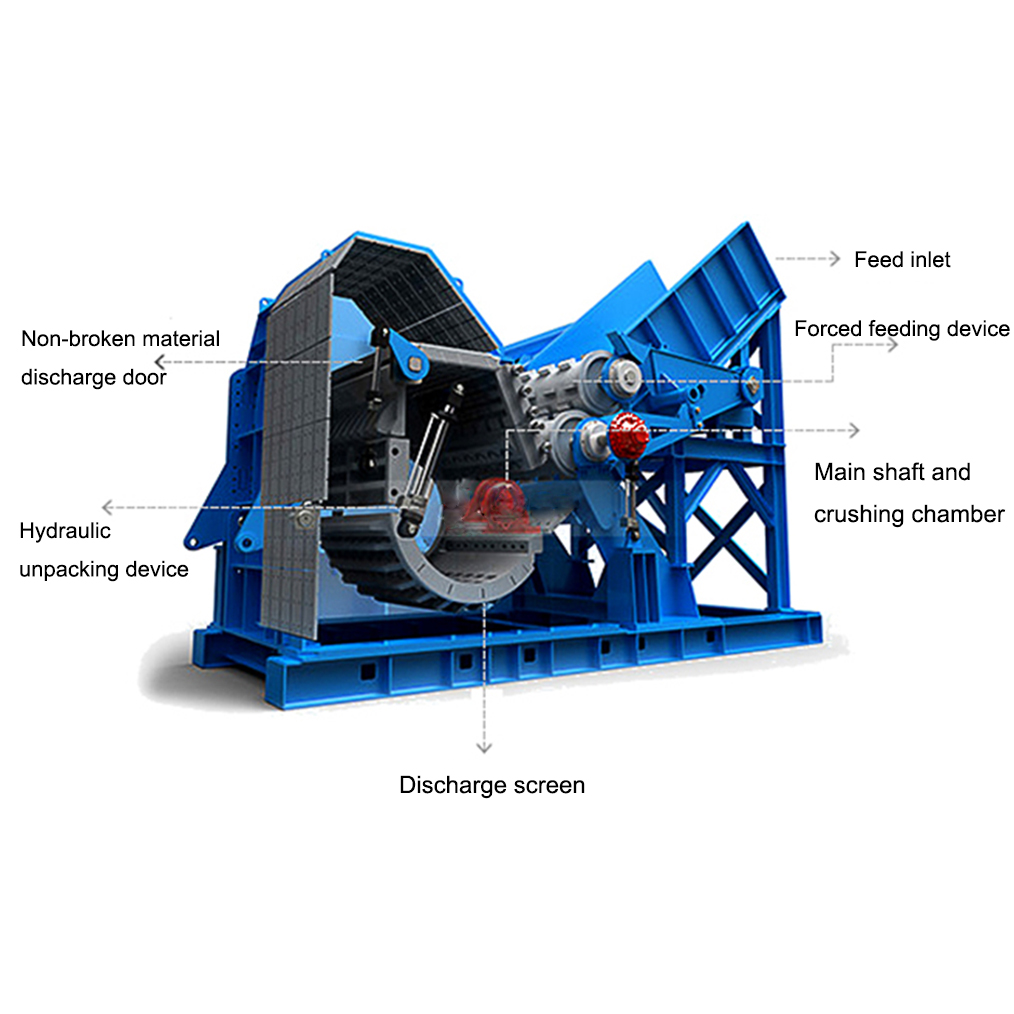

working principle

This equipment relies on a high-speed rotating blade to process oil filter cartridges, breaking them down into fragments. As the filter cartridge enters the working area, the blade immediately rotates at high speed, shredding both the outer shell and internal components of the cartridge. This shredding method allows the metal parts and filter paper materials inside the cartridge to be separated for subsequent reuse. Since it is only shredded through physical means without undergoing chemical changes, the purity of various materials can be ensured, creating favorable conditions for the next stage of processing. In practical operation, this technology enables the oil filter crusher to quickly process numerous discarded filters, increasing the reuse rate. Moreover, its crushing performance is consistently reliable, ensuring that filters of various sizes and materials can be fully crushed after adjusting the parameters.

Surgical parameters

| Model | Power(kw) | Output(kg/h) | Host Size(m) |

| 600 | 18.5-22 | 200-400 | 2.6×1.5×1.85 |

| 700 | 20-30 | 400-800 | 2.8×1.8×1.95 |

| 800 | 30-37 | 500-1000 | 2.9×2.3×2.0 |

| 900 | 37-45 | 600-1200 | 2.9×2.5×2.13 |

| 1000 | 75-110 | 1000-2000 | 3.2×2.6×2.3 |

| 1300 | 90-110 | 3000-5500 | 3.8×3.0×2.8 |

Hot Line:008613044703777

Time:9:00 - 18:00