Aluminum scrap crusher

- 【Feeding Size】:≤1000mm

- 【Processing capacity】:0.6T/h-16T/h

- 【Motor power】:30-450kw

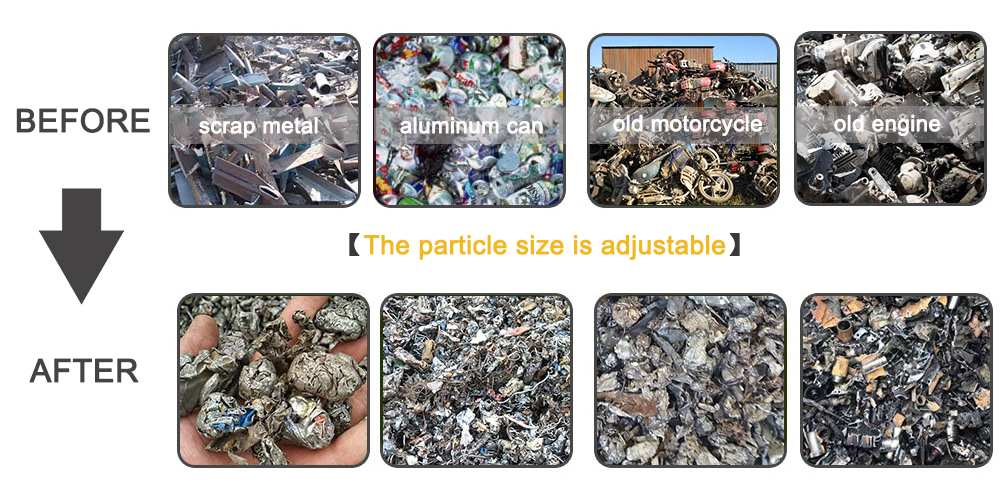

- 【Handling materials】:Waste steel, bicycles, motorcycles, car shells, cans, paint buckets, iron sheets, color steel tiles, and other waste thin and light metals ...

【Keyword】:

- Aluminum profile crusher

- bridge-cut aluminum crusher

- raw aluminum crusher

- aluminum alloy crusher

Product Introduction

In the field of aluminum scrap recycling, aluminum scrap crushers (aluminum alloy crushers) are emerging as core equipment for resource recycling. Specifically designed to handle scrap materials such as wrought aluminum, raw aluminum, aluminum alloys, and bridge-cut aluminum, these crushers convert scrap aluminum alloys of varying materials and sizes into high-purity chips through crushing and sorting operations, providing essential raw materials for aluminum casting production. This technology not only propels aluminum scrap recycling to become a significant source in the casting industry, but also stands out as a highly potential entrepreneurial investment project due to its remarkable economic benefits and environmental advantages.

The scrap aluminum crusher (aluminum alloy crusher) is a crushing equipment that processes scrap aluminum alloys of different materials, sizes, and shapes into scrap aluminum alloy chips of a specified size. The equipment consists of a metal crusher housing, crusher base, motor, electrical cabinet, and other components. It can be customized according to customer requirements to crush scrap aluminum materials into various sizes of materials. In recent years, the recycling of scrap aluminum alloys has become an important source of aluminum for casting. This equipment has good economic benefits and is environmentally friendly, making it a rare entrepreneurial investment project.

1. The aluminum scrap crusher utilizes a high-speed rotating hammer head, combined with a counterattack lining plate, to strike and crush aluminum scrap materials through the application of power and inertia;

2. The crushed material from the aluminum scrap crusher is conveyed through a vibrating conveyor and a belt conveyor, and then passed through a magnetic separator to separate ferrous materials from non-ferrous materials;

3. After separation, the metal materials, due to the mixing of various non-ferrous metals, need to be further separated by an eddy current separator to obtain pure aluminum scrap particles;

4. The scrap aluminum crusher, in conjunction with other conveying equipment, feeding equipment, sorting equipment, and dust removal equipment, forms a complete scrap aluminum crushing production line. The entire crushing process includes metal pressing and feeding, screening, conveying, dust removal, and metal-nonmetal sorting.

Product advantages

Equipped with high-performance alloy blades, it can quickly process a large quantity of scrap metal with uniform crushing results.

It supports an automatic control system, enabling one-click start, intelligent monitoring, and fault alarms, making it convenient for use and maintenance.

It is capable of shredding various metals such as iron, steel, and aluminum, and can also handle waste cables, scrap steel bars, etc., making it suitable for a wide range of application scenarios.

The equipment is made of high-strength wear-resistant materials, extending its service life and reducing maintenance costs.

working principle

Waste aluminum is crushed by a crusher, and dust removal equipment is used to remove lightweight materials and dust during the crushing process. Metals primarily containing iron are separated by a magnetic separator, and then aluminum and plastic are separated by an eddy current separator. This production line is fully controlled by PLC and monitored dynamically in real time. It features low unit energy consumption, large processing capacity, good economic efficiency, low maintenance costs, and good processing results. The entire waste aluminum crushing production line consists of a belt conveyor, a crusher, a magnetic separator, an eddy current separator, a dust collector, and a PLC control cabinet.

Surgical parameters

| Model | Power(kw) | Output(kg/h) | Host Size(m) |

| 600 | 18.5-22 | 200-400 | 2.6×1.5×1.85 |

| 700 | 20-30 | 400-800 | 2.8×1.8×1.95 |

| 800 | 30-37 | 500-1000 | 2.9×2.3×2.0 |

| 900 | 37-45 | 600-1200 | 2.9×2.5×2.13 |

| 1000 | 75-110 | 1000-2000 | 3.2×2.6×2.3 |

| 1300 | 90-110 | 3000-5500 | 3.8×3.0×2.8 |

Hot Line:008613044703777

Time:9:00 - 18:00